Where it is impractical or inefficient to bring the equipment to be fuelled to a fuel island, it is usual for the fuel to be brought tot he equipment using a fuel bowser. In the past this has lead to a reduction in fuel security, or at least a reliance on written fuelling information from the bowser driver. Because the jigsaw system uses the mobile data network, refuelling from a bowser is now as secure as on a static fuel site.

Typically, the fueller has to park the fuel bowser adjacent to the equipment to be fuelled then reel out the hose to the fuelling point. Whether the fueller ID’s the vehicle first and pulls out a charged hose, or inserts the nozzle and walks back to the fuel terminal, there is a much increased possibility that fuel will be spilled.

Safer Fuelling

Most Relevant Reports :

- Transaction listings by group and pump - see any fuellings which are not normally fuelled by the bowser.

- Period Stock reports - Track how much fuel is delivered through the bowser so that any sudden rises in fuel usage are obvious.

- Group Fuel Usage to identify fuel use by equipment type

- Continuous Stock Management from initial delivery on site, from static tanks to mobile bowsers, from bowser to final fuel user - fuel stock movement is logged at each stage.

- Responsible Driver ID is logged along with other fuel parameters.

- The system automatically generates real time fuelling information highlighting vehicles and people using excessive amounts of fuel. The web service lets you quickly delve in to the data behind these issues.

- All vehicles and plant equipment fuellings are monitored and reported on in the same place whether mobile or static refuelling.

- Both Mobile and Static tank contents are viewable through the web service in REAL TIME

Useful System Features :

Options to consider :

Airports, Quarries, Highway Maintenance ...

Mobile Refuelling

In the past, fuel management systems have treated the tank on the back of a bowser as just another vehicle so that this was where fuel and stock management stopped. The Jigsaw system has a Stock Transfer Tag which allows a normal refuelling at the pump to be used to fill the bowser, but treats the resulting transaction as a stock transfer from the static tank to the bowser so that stock management is maintained right to the point of fuelling.

Joined Up Stock Management.

In most cases, there is only one product being dispensed, so the Jigsaw Nova system is the obvious choice. Its small size and ability to operate from 12 or 24 Volts mean that it is easy to site on the fuel bowser. If more products are to be managed, or alphanumeric data entry is required, then the Jigsaw Eclipse may be used instead as it too has been designed to operate from a DC supply. Both systems will operate with both the FuelWand and FuelGuard add-ons.

Mobile Fuel Management Hardware :

- Mobile Refuelling can be as simple as the driver simply typing in a Plant or Vehicle ID before fuelling, but this can be open to abuse or mistakes. A more secure system will see the driver issued with a Jigsaw FuelWand where a tag is permanently fitted to the vehicle and the driver scans the tag before fuelling can take place.

- If mileage or engine hours are to be captured, then the FuelWand may be augmented by fitting a FuelGuard to the equipment so that the mileage or engine hours are automatically gathered at the time of fuelling. Mixed operation is possible with some vehicles not gathering mileages, some have manually typed mileage input, and some automatically gathering mileage using the FuelGuard system.

- For the best stock management, the Tank Transfer key should be used to transfer stock from a fixed tank to the bowsers tank.

- Tank Gauging is not very practical on a mobile bowser, but by fitting a tank gauge to the static tank, it is possible to verify the static fuel stock, and also the amount delivered from that tank to the bowser.

- Make sure that emergency fuel flow controls are considered. Long hoses dragged across open ground can lead to fuel spills and dry break hose couplings should be considered.

- On many sites where mobile refuelling is required, there is usually a requirement to also fill fuel cans. By attaching RFID tags to these cans, the amount of fuel issued to them may be managed along with the rest. This type of open ended fuel issue is often an area where fuel goes missing.

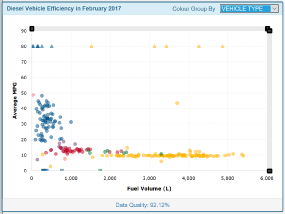

Unique Jigsaw Vision Tiles give Real Time information - this one highlights any units taking more fuel than their peers.

Most Relevant Vision Tiles :

- Site Throughput Growth Curve - Track Fuel Used over time - any sudden increases are made obvious.

- Group MPG Comparison Swarm Graph - Easily compare equipment types and highlight any taking excessive fuel.

- Vehicle Highest Fuel Usage by Group - Highlight any individual Vehicle taking more than its peers.

- CO2 Emissions

The Jigsaw FuelWand has been designed to give the operator control of the filling process at all times. The Fuelwand is a hand held ID Tag reader which is linked to the fuel controller by radio. With the hose deployed, the fueller simply reads a tag fixed to the equipment being fuelled and the fuel starts to flow. Because the fueller is at the point of delivery during the fuelling process, there is much less possibility of a fuel spill.

| Eclipse |

| Nova |

| Jigsaw Fuel Web Service |

| Jigsaw Tank Guard |

| Pump Integrated Eclipse |

| Jigsaw EasyFuel |

| Jigsaw TeleTag |

| Fuel Management ID Devices |