Any Fuel Management System worth it’s salt will be able to tell you, in real time, how much fuel is in any tank on the system - so why bother with the expense of a tank gauge ? At first glance it’s not obvious but, as a check on the rest of the system, and for spotting external events such as fuel theft or poor pump calibration a gauge is invaluable.

Without a gauge, stock is managed like an accounting ledger - initial stock plus deliveries minus drawings equals current stock. As drawings take place the stock volume decreases, as deliveries are received, the stock is added to. This is commonly known as a Book Stock value.

With timely input of the deliveries through the web site, and real time transaction updates, the stock figure displayed on the system is always up to the minute. There are, however, issues that mean that the stock in the tank doesn’t match what the book stock says. If a tank was dipped every quarter say, and a discrepancy of 2000 litres was discovered, it would be very hard to discover where the fuel had gone. That’s were tank gauging comes in.

Checks and balances

Why do I need tank Gauging ? ...

Tank Gauging

One of the most common problems is human error. A delivery would normally be, say, 30,000 Litres and the same person enters this figure in to the FM system each time. A delivery of 28,000 litres comes in and this is entered (because of habit) as 30,000 Litres – three months later there’s an unexplainable discrepancy. Looking back at the deliveries everything looks fine so it’s difficult to spot without going back through each fuel invoice.

Another problem is pump calibration. A pump will display and tell the fuel management system that it has dispensed, say, 200 litres, when in fact it has delivered 202. Over time, the tank ends up having less in than is calculated by the system leading to stock write offs. It can, of course work the other way and the pump is delivering 198 litres when it says 200 and you end up with more stock in the tank.

Less often, there’s the possibility of short deliveries where you are billed for 30,000 litres but only get 28,000, and, finally there is the possibility of fuel being stolen from the tank.

All of these issues are quickly detected if a tank gauge is fitted

Causes of Stock Issues

In 2017, Jigsaw removed an existing fuel management system that had been installed for over 10 years and fitted a new Jigsaw Eclipse linked to the existing gauge. They had been complaining to their old fuel management supplier for some time that their stock usage figures didn’t tie in with what they were being invoiced. They had been told to add a tank gauge to the system to try and identify the issue, but to no avail.

Within two weeks of the Jigsaw system being fitted, it had spotted and highlighted a discrepancy in fuel stocks occurring as a step fall of around 1000 litres on a Sunday evening. The staff on the site initially didn’t believe that fuel could have been stolen as the site is well run and was manned by security staff at the time the fuel level fell. A week later, another 1000 litres went. The Jigsaw system raised e-mail and text alarms, but the security staff on site couldn’t see any issues at the tank.

Is Fuel Theft from Tanks an Issue ? - Imagine This ...

The jigsaw system can interface to just about any Tank Gauge Unit that has an electronic communications interface. The more common are OLE, Gilbarco Veeder-Root (GVR), OPW, Franklin, Piusi OCIO, I-Level etc. These use various technologies to measure fuel depth, then calculate the volume of fuel from configured tank dimensions.

The accuracy of the gauge depends on how accurately it can measure the depth of fuel. The least expensive can measure with an accuracy of around 2 Cm, the most expensive claim to measure to around 0.1 mm - you get what you pay for. An accuracy of around 5 mm is usually sufficient for good stock management.

What Type of Gauge ?

The day after, a service engineer was called to check the system as the site still thought it must be a hardware problem. The engineer checked the pipe work and found a permanent tapping point on the diesel line. From here, a pipe led almost 300 M to a 1000 litre tank buried in a river bank. At this spot there was an electric suction pump and a mains socket, which was wired from a lamp post 100 M away. From the tank there was 500 M length of pipe to a more convenient point where barrels could be filled. The whole set up had obviously be installed and used over many years as vegetation and even trees had grown around and over much of the pipe work and equipment.

1000 Litres a week for years ! A problem was suspected but it was only after the Jigsaw system was fitted that the cause was identified and the theft stopped.

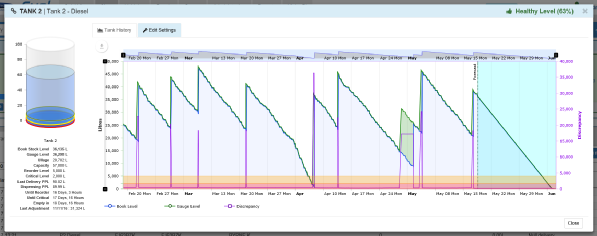

As each fuelling transaction takes place and is sent to the web server, the gauge level is also sent. This allows the system to plot, in real time, the book stock level against the gauge level so that any discrepancy is immediately apparent. Even when there is no one looking at the data, the system may be set to raise e-mail, or even text alerts if a sudden fall in tank stock is seen. The Fuel island terminal is constantly on guard for stock falls when there is no activity on the fuel pumps.

Tank Stock Display

This site is almost perfect. The blue and green lines are virtually in the same place and there is little discernible drift over three months in the red discrepancy line. The red peaks showing the time between the gauge seeing deliveries and them being entered are minimal and the steady rate of fall means it is simple for the system to calculate when the stock will next need reordering.

The graph of Book Stock against Gauge stock should track each other perfectly. This site shows a problem over time with the pump over delivering resulting in an general trend of and increasing discrepancy (bottom red line) There also appear to be several step changes which may be evidence of incorrect data entry, short deliveries or theft.

| Eclipse |

| Nova |

| Jigsaw Fuel Web Service |

| Jigsaw Tank Guard |

| Pump Integrated Eclipse |

| Jigsaw EasyFuel |

| Jigsaw TeleTag |

| Fuel Management ID Devices |